With the rapid development of wearable electronics, neurorehabilitation, and brain-machine interfaces in recent years, there has been an urgent need for methods to conformally wrap thin-film electronic devices onto biological tissues to enable precise acquisition and regulation of physiological signals.

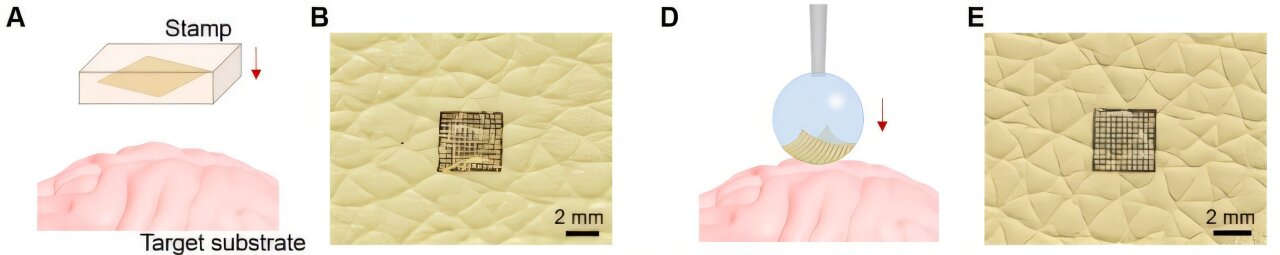

Conventional methods typically rely on external pressure to force devices onto conformal contact. However, when applied to uneven three-dimensional surfaces such as skin, brain, or nerves, they generate significant internal stress which can easily damage fragile metal circuits and inorganic chips. This is an obstacle to the advancement of flexible electronics.

In a study published in Science, Prof. Song Yanlin’s team from the Institute of Chemistry of the Chinese Academy of Sciences, along with collaborators from Beijing Tiantan Hospital, Nanyang Technological University, and Tianjin University, propose a new film transfer strategy named as drop-printing, which has potential applications in bioelectronics, flexible displays, and micro-/nano-manufacturing.

In this strategy, droplets were used to pick up and transfer ultrathin films. When deposited onto the target surface, the droplet formed a temporary lubricating layer between the film and the substrate, which allowed stress generated during film deformation to be dynamically released through localized sliding, preventing the device from rupture. By controlling the dynamics of the three-phase contact line, the strategy achieved high positional accuracy.

Experiments showed that the drop-printing strategy not only enabled the conformal wrapping of nanometer-thick, non-stretchable electronic films onto optical fibers, plant surfaces, and even microorganisms, but also allowed for the transfer of stem cell films by adjusting the droplet composition.

In animal studies, 2 µm-thick silicon-based films were successfully printed onto the surfaces of nerves and brains, forming conformal bioelectronic interfaces. Using these interfaces, infrared light was able to induce periodic limb movements in the animals, demonstrating precise spatiotemporal control of the neural activity.

This work provides new insight into the damage-free attachment of ultrathin films onto complex three-dimensional surfaces by dynamically releasing stress during conformal deformation.

More information:

An Li et al, Drop-printing with dynamic stress release for conformal wrap of bioelectronic interfaces, Science (2025). DOI: 10.1126/science.adw6854

Chinese Academy of Sciences

Citation:

‘Drop-printing’ shows potential for constructing bioelectronic interfaces that conform to complex surfaces (2025, September 19)

retrieved 19 September 2025

from https://techxplore.com/news/2025-09-potential-bioelectronic-interfaces-conform-complex.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.